🌟 Discover Genuine Connections at Anpip.com! 🌟

Ready to elevate your online social experience? Look no further than Anpip.com! Join now for live chats, Chatroulette, video chats, streams, and even earn with gifts! Expand your social circle and find meaningful connections in a fun environment.

🚀 Take the first step today! Visit Anpip.com for more info! 🚀

Evolution of Cyber3Dprinting Technology

The Evolution of Cyber3Dprinting technology has been transformative over the past 30 years, combining cyberspace with 3D printing to revolutionize the manufacturing industry. Historical advancements, such as the founding of 3D printing technology in 1980 and the development of Stereolithography in 1986, have played a critical role in shaping the present landscape of additive manufacturing. These breakthroughs have led to faster turnaround times, enhanced attention to detail, and improved production processes, driving the widespread adoption of 3D printing technologies across various industries.

Overview of Cyber3Dprinting

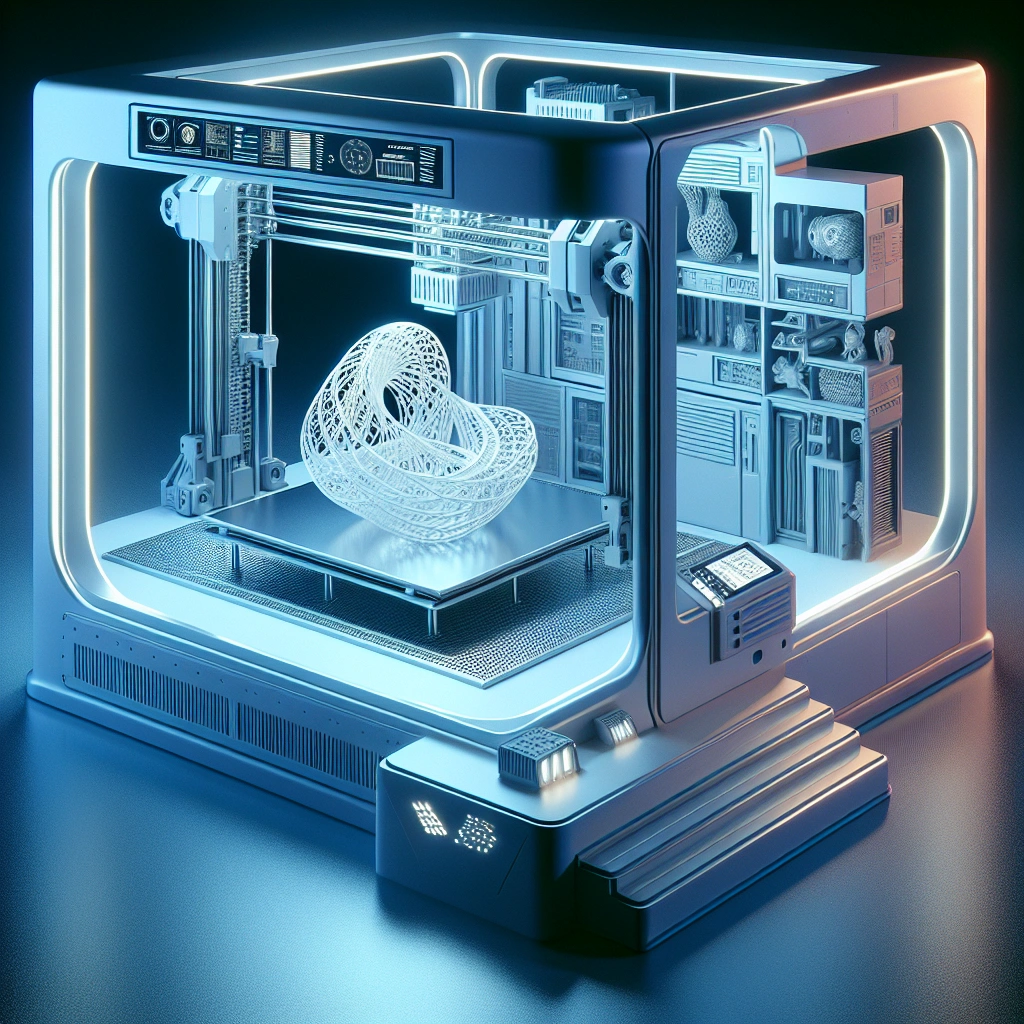

Cyber3Dprinting, a cutting-edge technology, combines cyberspace with 3D printing, revolutionizing the manufacturing industry. This innovative process integrates traditional 3D printing with digital advancements, enabling the creation of intricate designs and products with utmost precision and efficiency. By utilizing Cyber3Dprinting, businesses can streamline production processes, reduce costs, and enhance product quality.

To provide an overview of Cyber3Dprinting, it’s essential to understand its core components. This technology involves using computer-aided design (CAD) software to create virtual models that are then translated into physical objects through 3D printers. The integration of cyber components allows for remote monitoring and control, enhancing customization and scalability in manufacturing.

For more detailed information, you can read about The Digitalisation of Science, Technology, and Innovation that discusses the key developments and policies in the realm of 3D printing and digital manufacturing.

Historical Advancements in Cyber3Dprinting

The historical advancements in Cyber3Dprinting have been remarkable, shaping the present landscape of manufacturing. Over 30 years, additive manufacturing technology, including 3D printing, has evolved exponentially from its initial inception to becoming a pivotal tool in various industries.

One pivotal milestone was in 1980 when the first 3D printing technology was founded, paving the way for future innovations. Another significant achievement was in 1986 when Chuck Hull patented Stereolithography, leading to the establishment of 3D Systems, Inc. These breakthroughs spurred the widespread adoption of 3D printing technologies, propelling the industry forward.

Another example of the impact of 3D printing on manufacturing is its role in driving faster turnaround times and enhancing attention to intricate details, positively transforming the production processes.

For more insights, you can explore how 3D Printing Milestones have influenced the past and future of manufacturing, providing a comprehensive look at the evolution of this groundbreaking technology.

The Advantages of Cyber3Dprinting

Cyber3Dprinting offers unparalleled efficiency in project completion through rapid prototyping, reducing production timelines and lead times significantly. The technology is cost-effective, minimizing material wastage and reducing expenses by eliminating the need for costly tooling. Its unmatched customization and design flexibility empower businesses to create bespoke products tailored to individual customer specifications, driving innovation and speeding up product development cycles.

Efficiency in project completion

Cyber3Dprinting offers unparalleled efficiency in project completion by reducing production timelines through rapid prototyping. Traditional manufacturing processes often involve extensive lead times for tooling and production setup, whereas Cyber3Dprinting allows for immediate production of complex parts without the need for molds or dies.

One key advantage is the ability to iterate designs quickly, enhancing the development cycle and decreasing time-to-market significantly. For instance, automotive companies utilizing Cyber3Dprinting can swiftly prototype vehicle components, leading to faster innovation and product launches. This efficiency saves vital time for businesses across various industries.

Moreover, virtual design validation tools integrated with Cyber3Dprinting enable companies to detect and rectify issues early in the design phase, further boosting productivity and reducing project delays. By streamlining the development process, Cyber3Dprinting optimizes project timelines and maximizes operational efficiency.

Cost-effectiveness of Cyber3Dprinting technology

The cost-effectiveness of Cyber3Dprinting technology lies in its ability to minimize material wastage and reduce production expenses. Unlike traditional manufacturing methods that often lead to excess material scrap, Cyber3Dprinting only uses the necessary material for each part, cutting down on material costs substantially.

Additionally, the elimination of costly tooling requirements in Cyber3Dprinting translates to lower setup costs, especially for short production runs or customized orders. Companies can capitalize on this cost-efficient technology by avoiding high initial investments in molds and dies, making it an attractive option for small to mid-sized businesses.

Moreover, the scalability of Cyber3Dprinting technology allows for production on-demand, reducing inventory carrying costs and improving cash flow management. By optimizing resource utilization and minimizing overhead expenses, Cyber3Dprinting offers long-term cost savings for organizations seeking competitive pricing strategies.

Customization and design flexibility

The unparalleled customization and design flexibility offered by Cyber3Dprinting revolutionize product development by enabling intricate designs and tailored solutions. Companies can leverage this technology to create bespoke products tailored to individual customer specifications or unique design requirements.

With Cyber3Dprinting, designers have the freedom to experiment with complex geometries and intricate structures that were once unattainable through traditional manufacturing methods. This design flexibility empowers businesses to unleash their creative potential and bring innovative products to market swiftly.

Furthermore, the ability to rapidly prototype and test multiple design iterations with Cyber3Dprinting facilitates efficient product development cycles, reducing time and costs associated with manual prototyping. By offering unmatched design freedom, this technology paves the way for groundbreaking innovations across industries.

| Advantages of Cyber3Dprinting |

|---|

| 1. Enhanced efficiency in project completion |

| 2. Cost-effectiveness in production |

| 3. Unmatched customization and design freedom |

For more detailed information, you can read about the cost comparison of 3D printing vs. traditional manufacturing and how Cyber3Dprinting drives innovation in design flexibility.

Implementation of Cyber3Dprinting in Projects

3D printing, also known as additive manufacturing, is witnessing a groundbreaking integration into existing project workflows across various industries. The seamless fusion of Cyber3Dprinting technology into conventional processes revolutionizes the way products are developed and manufactured.

Integration into existing project workflows

The incorporation of Cyber3Dprinting technology allows for rapid prototyping and on-demand manufacturing within project workflows. Teams can now swiftly iterate designs, reducing time-to-market and overall development costs. By seamlessly integrating Cyber3Dprinting, projects gain flexibility and efficiency in product development phases.

Print spare parts yourself with the 3D printing platform

One of the most significant advantages of Cyber3Dprinting in projects is the capability to print spare parts on-demand. This eliminates the need for bulky inventories and long lead times for spare part orders. Companies can now embrace a just-in-time production model, ensuring operational continuity and cost-efficiency.

Scope for new developments and product improvements

Cyber3Dprinting technology offers an extensive scope for innovation and product enhancement. Through the implementation of advanced materials and design iterations, projects can achieve superior product quality and performance. Moreover, the ability to quickly prototype and test new ideas accelerates the pace of product development.

Leveraging the power of Cyber3Dprinting in projects not only streamlines workflows but also opens up avenues for creative solutions and sustainable practices. The adaptability of this technology ensures that projects stay ahead of the curve in a rapidly evolving landscape.

For more detailed insights on how Cyber3Dprinting is transforming industries, check out 3D printing on the construction site and How 3D Printing is Transforming the Spare Parts Industry.

Cyber3Dprinting in Innovation Projects

Cyber3Dprinting is revolutionizing innovation projects by accelerating design iterations, facilitating quick adjustments, and enabling cost-effective prototyping. It plays a crucial role in enhancing creativity, collaboration, and experimentation among teams, leading to breakthroughs in product development. By leveraging Cyber3Dprinting technology, businesses can optimize production processes, create personalized products, and stay competitive in the market landscape.

Role of Cyber3Dprinting in innovation projects

Cyber3Dprinting is revolutionizing innovation projects by enabling rapid prototyping and cost-effective product development. It plays a crucial role in accelerating the design iteration process, allowing for quick adjustments and improvements.

By leveraging Cyber3Dprinting technology, companies can test multiple concepts efficiently, leading to enhanced creativity and innovation.

The integration of Cyber3Dprinting in innovation projects empowers teams to transform ideas into tangible prototypes swiftly, facilitating seamless collaboration between designers, engineers, and stakeholders. This streamlined workflow fosters a culture of innovation and experimentation, driving progress and breakthroughs in product development.

Cyber3Dprinting serves as a catalyst for pushing boundaries and exploring new possibilities in the innovation landscape.

Moreover, Cyber3Dprinting enhances the customization and personalization of products, catering to individual consumer preferences and market demands. Its flexibility and versatility allow for the creation of unique designs and tailored solutions, giving businesses a competitive edge in delivering innovative offerings that resonate with their target audience.

By harnessing the potential of Cyber3Dprinting, organizations can stay ahead in the ever-evolving market.

Potential for enhancing products and services

The potential of Cyber3Dprinting in enhancing products and services is vast and transformative. By leveraging this cutting-edge technology, businesses can optimize their production processes, reduce time-to-market, and minimize operational costs.

Cyber3Dprinting enables the creation of complex geometries and intricate designs that were previously unattainable through traditional manufacturing methods.

Furthermore, Cyber3Dprinting opens up a world of possibilities for product innovation and differentiation. Companies can develop prototypes rapidly, test functionalities effectively, and gather valuable feedback early in the design phase.

This iterative approach not only accelerates product development cycles but also ensures the final products meet the highest standards of quality and performance.

The customization capabilities of Cyber3Dprinting enable businesses to offer personalized products tailored to individual preferences and specific requirements. This level of customization enhances customer satisfaction, fosters brand loyalty, and drives competitive advantage in the market.

By embracing Cyber3Dprinting, organizations can transform their product offerings into bespoke solutions that resonate with their target audience.

Examples of successful Cyber3Dprinting projects

One notable example of successful Cyber3Dprinting projects is in the healthcare industry, where 3D printing technology is revolutionizing the production of personalized medical devices, prosthetics, and implants. Companies like Biomedical Innovations are leveraging Cyber3Dprinting to create custom-fit solutions for patients, enhancing comfort and functionality while reducing lead times and costs.

Another compelling example of Cyber3Dprinting innovation is in the aerospace sector, where companies like are using 3D printing to manufacture lightweight and complex aerospace components. By harnessing the capabilities of Cyber3Dprinting, these companies have achieved significant advancements in structural design optimization, material efficiency, and overall performance.

In the automotive industry, stands out as a pioneer in utilizing Cyber3Dprinting for rapid prototyping, tooling, and part production. This approach has enabled MotorWorks to streamline their manufacturing processes, reduce production lead times, and increase operational efficiency. By embracing Cyber3Dprinting, MotorWorks has successfully enhanced their product offerings and gained a competitive edge in the market.

Cyber3Dprinting is a game-changer in innovation projects, offering unparalleled opportunities for creativity, customization, and efficiency. By harnessing the power of this revolutionary technology, businesses can drive innovation, enhance their products and services, and stay ahead in a rapidly evolving market landscape.

Call to Action:

Ready to elevate your online experience? Look no further than Anpip.com! Explore a world of live chats, Chatroulette, video chats, streams, and even the chance to earn gifts. Join now to expand your social circle and forge genuine connections in a fun online setting. Discover more at Anpip.com today!

Maximizing the Potential of Cyber3Dprinting

Utilizing Cyber3Dprinting for new product development

Cyber3Dprinting has revolutionized the way new products are developed by offering rapid prototyping capabilities, enabling companies to bring innovative ideas to life quicker than ever. By leveraging this cutting-edge technology, businesses can streamline their product development process, from initial design concepts to final production stages, reducing time-to-market significantly.

One of the key advantages of utilizing Cyber3Dprinting for new product development is the ability to create intricate and complex designs that traditional manufacturing methods couldn’t achieve. This enables designers to push the boundaries of creativity and innovation, leading to the development of products that are not only visually stunning but also highly functional.

Through Cyber3Dprinting, companies can easily iterate on their product designs, making modifications and improvements on the go without the need for expensive tooling or lengthy rework processes. This iterative approach allows for faster validation of ideas, ultimately leading to the creation of more refined and market-ready products.

Furthermore, Cyber3Dprinting technology offers a cost-effective solution for small-batch production runs, allowing businesses to test the market demand for new products without committing to large-scale manufacturing. This flexibility minimizes financial risks while maximizing the potential for market success, making Cyber3Dprinting a valuable tool for new product development.

In essence, Cyber3Dprinting opens up a world of possibilities for companies looking to innovate and disrupt traditional product development processes. By embracing this technology, businesses can unlock new levels of creativity, efficiency, and cost-effectiveness, ultimately maximizing their potential for success in today’s competitive market landscape.

Enhancing project outcomes with Cyber3Dprinting technology

When it comes to project outcomes, Cyber3Dprinting technology plays a crucial role in enhancing the overall quality, efficiency, and success rates of various projects across industries. By integrating Cyber3Dprinting into project workflows, organizations can achieve greater precision, speed, and customization in their deliverables, leading to superior outcomes and client satisfaction.

One significant benefit of leveraging Cyber3Dprinting technology in project management is the ability to create highly detailed and accurate prototypes that closely resemble the final product, enabling stakeholders to visualize and approve designs more effectively. This level of clarity reduces misunderstandings, rework, and project delays, ensuring smoother project execution and successful outcomes.

Moreover, Cyber3Dprinting facilitates rapid iteration and testing of project components, allowing teams to identify and address potential issues early in the development cycle. This proactive approach enhances project quality, minimizes risks, and ensures timely delivery, ultimately leading to improved project outcomes and client satisfaction.

By harnessing the power of Cyber3Dprinting technology, project managers can optimize their processes, mitigate risks, and drive innovation in project delivery, positioning their organizations for long-term success in a fast-paced and dynamic business environment. With enhanced project outcomes, companies can increase their competitiveness, reputation, and profitability, solidifying their position as industry leaders.

Leveraging Cyber3Dprinting for future advancements

Looking towards the future, Cyber3Dprinting technology presents unprecedented opportunities for advancements in various fields, including healthcare, aerospace, automotive, and beyond. By leveraging the continuous innovation and evolution of Cyber3Dprinting capabilities, industries can unlock new frontiers of possibilities and drive groundbreaking advancements in product development, research, and beyond.

In the healthcare sector, for example, Cyber3Dprinting is revolutionizing medical device manufacturing, prosthesis development, and organ transplantation by enabling precise customization, faster production, and improved patient outcomes. This transformative technology is set to revolutionize patient care, treatment efficacy, and overall healthcare quality in the coming years.

In the aerospace and automotive industries, Cyber3Dprinting is paving the way for the design and production of lightweight, durable components, enhancing vehicle performance, fuel efficiency, and safety standards. By leveraging advanced Cyber3Dprinting materials and techniques, manufacturers can optimize their processes and drive innovation in aircraft, automotive, and spacecraft manufacturing, setting new benchmarks for industry standards.

By embracing the potential of Cyber3Dprinting for future advancements, industries can stay at the forefront of innovation, competitiveness, and sustainability, leading to a brighter and more technologically advanced future for all. The possibilities are limitless, and the potential for groundbreaking discoveries and advancements is truly endless.

How Can Cyber3Dprinting Revolutionize Your Projects?

Cyber3Dprinting revolutionizes projects by enhancing efficiency, precision, and innovation in project management. By enabling rapid prototyping, real-time adjustments, and virtual simulations, Cyber3Dprinting streamlines project timelines, reduces costs, and mitigates risks. The technology empowers project managers to achieve better communication, improved design visualization, and faster product development, ultimately leading to enhanced project success and competitiveness.

Exploring the impact of Cyber3Dprinting on project management

Cyber3Dprinting brings a revolutionary shift in project management by enhancing efficiency and precision. Incorporating Cyber3Dprinting allows for rapid prototyping and real-time adjustments to designs, streamlining project timelines. Moreover, the digital nature of Cyber3Dprinting reduces the probability of human errors in project execution, ensuring accuracy in complex tasks.

Cyber3Dprinting empowers project managers to create detailed prototypes and visual representations of projects, facilitating better communication across teams and stakeholders. This advanced technology enables virtual simulations of project outcomes, aiding in risk assessment and mitigation strategies before actual implementation. By utilizing Cyber3Dprinting, project managers can achieve cost savings and time efficiencies, optimizing project resources effectively.

In the realm of project management, the integration of Cyber3Dprinting propels innovation by fostering creative problem-solving and agile methodologies. The flexibility offered by Cyber3Dprinting allows for iterative improvements and customization, catering to diverse project requirements without significant disruptions. This innovative approach to project management sets a new standard for industry competitiveness and project success in a technology-driven era.

Case studies showcasing the transformative power of Cyber3Dprinting

Case Study 1: Architecture Design Enhancement

In a recent project, an architectural firm utilized Cyber3Dprinting to enhance design visualization and client engagement. By creating 3D-printed models of proposed structures, the firm effectively communicated design concepts, leading to faster client approvals and improved project collaboration.

Case Study 2: Product Prototyping Efficiency

A tech startup leveraged Cyber3Dprinting to accelerate product development by virtually testing prototypes before physical production. This approach significantly reduced time-to-market, allowing the company to respond swiftly to market demands and customer feedback, ultimately enhancing product quality and customer satisfaction.

| Benefits of Cyber3Dprinting in Projects: |

|---|

| – Enhanced project visualization |

| – Reduced prototyping costs |

| – Improved design flexibility |

| – Streamlined project communication |

By embracing Cyber3Dprinting in project management, organizations can transcend traditional boundaries, accelerate project lifecycles, and achieve unprecedented levels of innovation and success.

Cyber3Dprinting for Sustainable Construction

Cyber3Dprinting is revolutionizing the construction industry by promoting sustainability through efficient material usage, reduced waste generation, and environmentally conscious building practices. The advanced technology allows for the creation of intricate designs with minimal resources, leading to carbon-neutral buildings and a circular economy within the construction sector. By incorporating environmental considerations from design to execution, Cyber3Dprinting projects can significantly reduce their environmental impact and contribute to a cleaner and greener construction industry.

Yes.

Promoting sustainability through Cyber3Dprinting

Cyber3Dprinting is revolutionizing the construction industry by promoting sustainability through efficient material usage and reduced waste generation. By utilizing advanced technologies in 3D printing, construction companies can significantly decrease their carbon footprint and contribute to a more eco-friendly environment. The precise nature of Cyber3Dprinting allows for the creation of complex designs with minimal resources, optimizing sustainability efforts in the construction sector.

To illustrate, 3D printing techniques in construction can lead to carbon-neutral buildings through the use of polymer composites that act as superior insulators, reducing energy consumption in the long run. This approach not only benefits the environment but also enhances the overall quality and longevity of constructed structures, aligning with sustainable development goals and green building practices.

Furthermore, Cyber3Dprinting promotes sustainability by striving to achieve a circular economy within the construction sector, where materials are recycled and repurposed efficiently. This closed-loop system reduces waste production and minimizes environmental impact, fostering a more sustainable approach to building infrastructure and architectural projects.

The integration of Cyber3Dprinting in construction processes offers a promising pathway towards sustainable development goals by promoting resource efficiency, reducing waste generation, and fostering environmentally conscious building practices.

Redefining construction processes with Cyber3Dprinting

Cyber3Dprinting is redefining traditional construction processes by introducing innovative techniques that streamline project timelines and enhance overall efficiency. Through the precise layering of materials and digital modeling, Cyber3Dprinting enables construction companies to accelerate the building process while maintaining high-quality standards.

By redefining construction processes, Cyber3Dprinting minimizes manual labor requirements, reduces construction errors, and enhances project scalability. The automated nature of Cyber3Dprinting ensures consistent output quality, leading to cost savings, faster project completion, and improved overall project outcomes.

Moreover, the customization capabilities of Cyber3Dprinting allow for intricate architectural designs and structural components to be executed with precision, offering architects and designers unparalleled creative freedom in their projects. This redefined approach to construction processes elevates the industry standard and sets new benchmarks for efficiency and innovation.

Cyber3Dprinting is revolutionizing construction methods, paving the way for a more streamlined, efficient, and technologically advanced approach to building infrastructure.

Incorporating environmental considerations in Cyber3Dprinting projects

The adoption of Cyber3Dprinting in construction projects presents a unique opportunity to incorporate environmental considerations from the initial design stages to the final execution. By prioritizing sustainable materials, energy-efficient processes, and waste reduction strategies, Cyber3Dprinting projects can significantly reduce their environmental impact and promote eco-friendly practices.

Incorporating environmental considerations in Cyber3Dprinting projects involves selecting recyclable and biodegradable materials, optimizing energy consumption during the printing process, and implementing waste management strategies to minimize ecological harm. These efforts ensure that Cyber3Dprinting projects align with eco-conscious practices, contributing to a cleaner and greener construction industry.

By integrating Cyber3Dprinting with sustainable construction practices, companies can not only achieve their project goals but also uphold their commitment to environmental stewardship. This harmonious balance between technological innovation and environmental responsibility sets a new standard for construction projects, driving the industry towards a more sustainable and resilient future.

To learn more about the environmental benefits of Cyber3Dprinting in construction and the implications for sustainable development, click here.

Cyber3Dprinting: A Future-Forward Approach

Cyber3Dprinting is not just a buzzword; it marks a significant shift in the future of manufacturing. As we delve into the realm of Cyber3Dprinting, we can anticipate several exciting advancements that will revolutionize traditional approaches to production and design.

Let’s explore the future trends, innovations, and collaborative opportunities that Cyber3Dprinting brings to the forefront.

Future trends in Cyber3Dprinting technology

- Decentralized Manufacturing: In the near future, Cyber3Dprinting is poised to enable decentralized manufacturing processes, allowing for on-demand production of goods locally or even at home.

- Integration with IoT: The integration of Cyber3Dprinting with the Internet of Things (IoT) will lead to smart production systems that can self-optimize, enhancing efficiency and reducing wastage.

- Bioprinting Advancements: Expect significant advancements in bioprinting technology, paving the way for the creation of personalized medical implants and even organs.

- Enhanced Materials: The future of Cyber3Dprinting will witness the development of novel materials with superior properties, expanding the applications of additive manufacturing.

For more detailed insights into emerging technology trends, explore the latest technology trends shaping our world.

Innovations on the horizon for Cyber3Dprinting

- Multi-Material Printing: Innovations in Cyber3Dprinting will focus on enabling multi-material printing capabilities, allowing for the creation of complex, functional prototypes and end-products.

- Speed and Scale: Expect advancements in printing speed and scalability, making Cyber3Dprinting a viable option for mass production in various industries.

- Nanotechnology Integration: The incorporation of nanotechnology in Cyber3Dprinting processes will enable the production of miniature, high-precision components for electronics and medical devices.

- AI-Powered Design: AI algorithms will play a significant role in optimizing designs for Cyber3Dprinting, reducing iteration times and enhancing product performance.

Explore the expanding 3D printing horizon in the industry with insights from this article on emerging printing technology trends.

Collaborative opportunities in Cyber3Dprinting research and development

- Academic-Industry Partnerships: Collaborations between academia and industry players will drive the research and development of Cyber3Dprinting technologies, fostering innovation and knowledge exchange.

- Global Research Consortia: Global research consortia will emerge to tackle challenges in Cyber3Dprinting, leveraging diverse expertise to push the boundaries of additive manufacturing.

- Cross-Disciplinary Innovation: Cross-disciplinary collaborations between experts in materials science, robotics, and computer science will lead to breakthroughs in Cyber3Dprinting technology.

- Funding Initiatives: Look out for funding initiatives supporting collaborative Cyber3Dprinting projects, encouraging experimentation and disruptive innovations in the field.

Dive deeper into efficient data utilization for smart manufacturing with insights from this study on cyber technologies.

Collaborative research is essential for driving Cyber3Dprinting forward, as illustrated in this work on efficient 3D model search algorithms.

Cyber3Dprinting represents a future-forward approach that promises to reshape the landscape of manufacturing and design. By staying abreast of the latest trends, innovations, and collaborative opportunities, businesses and researchers can harness the full potential of this transformative technology.

When delving into the world of Cyber3Dprinting, it becomes evident that the benefits are vast and promising for the future. This cutting-edge technology offers a myriad of advantages, from rapid prototyping to cost efficiency and design flexibility. Embracing Cyber3Dprinting means unlocking endless possibilities in product development and revolutionizing traditional manufacturing processes.

Looking at the key takeaways on the benefits of Cyber3Dprinting, it is crucial to highlight how this technology paves the way for customization, allowing for on-demand production tailored to specific needs. Additionally, the speed at which prototypes and final products can be created translates to quicker turnaround times and enhanced innovation in various industries. The reduced material wastage and sustainability aspects further underscore the positive impact Cyber3Dprinting can have on the environment.

As we gaze into the future of Cyber3Dprinting technology, exciting advancements and evolutions await. The continued refinement of materials used in the printing process, coupled with improved precision and resolution, will open doors to even more intricate designs and applications.

The integration of Artificial Intelligence and machine learning algorithms will further streamline the manufacturing process, optimizing efficiency and quality control.

The journey of Cyber3Dprinting is a fascinating voyage into the realm of innovation and progress. By harnessing the power of this revolutionary technology, industries across the board are set to experience a paradigm shift in production methodologies and design capabilities.

This transformative technology is not just a trend but a pivotal force shaping the future landscape of manufacturing and design industries.

For a deeper dive into the future trends and advancements in Cyber3Dprinting, you can explore relevant articles such as:

-

5 Predictions for the Future of Additive Manufacturing: Offering insights into the role of additive manufacturing in supply chain management and beyond.

-

Delving into the intertwined evolution of AI and 3D printing within the realm of frontier technologies.

Remember, Cyber3Dprinting isn’t just about creating objects; it’s about sculpting a future where imagination and technology converge to redefine the very essence of creation.

Join Anpip.com Today and Explore the World of Live Chats, Video Chats, and More!

🌟 Ready to make genuine connections and have fun online? Look no further than Anpip.com! 🌟

Join now to experience live chats, Chatroulette, video chats, streams, and even earn with gifts. Expand your social network and discover meaningful connections in a vibrant online environment. Don’t miss out on the excitement!

For more information or to get started, visit us at Anpip.com. Let’s connect and have an amazing time together!

Frequently Asked Questions

What is 3D printing?

3D printing is the process of creating a physical object from a digital model by layering materials.

What types of 3D printers are there?

There are various types of 3D printers including FDM, SLA, SLS, and DLP printers.

What types of materials can you print with?

You can print with materials such as plastics, metals, ceramics, and even food in 3D printing.

What objects can you 3D print?

You can 3D print a wide range of objects including prototypes, tools, spare parts, and even medical implants.

What is the major problem faced while 3D printing?

One major problem in 3D printing is the lack of standardization which can lead to quality and compatibility issues.

What are 5 facts about 3D printing?

3D printing is used in the film industry, it’s older than you think, it’s not just for prototyping, it’s called fashion, and it lets you print almost anything.

What is the main risk associated with 3D printing?

The main risks associated with 3D printing include environmental problems, gun and drug control issues, copyright infringement, and potential health hazards.

What is the risk of cybersecurity in 3D printing?

Common cybersecurity threats in 3D printing include deliberate insertion of defects, IP theft, data breaches, and potential cyberattacks due to cloud-based operations.

How to Combat Cybersecurity Risks in 3D Printing?

Combatting cybersecurity risks in 3D printing involves implementing the finest cybersecurity standards, securing sensitive data, monitoring for potential threats, and staying updated on the latest security measures.

What are the common cybersecurity threats associated with 3D printing?

Common cybersecurity threats associated with 3D printing include IP theft, data breaches, deliberate insertion of defects, and vulnerabilities to cyberattacks due to cloud-based operations.

What are 5 facts about 3D printing?

3D printing is used in the film industry, it’s older than you think, it’s not just for prototyping, it’s called fashion, and it lets you print almost anything.

What is the main risk associated with 3D printing?

The main risks associated with 3D printing include environmental problems, gun and drug control issues, copyright infringement, and potential health hazards.

What are the common cybersecurity threats associated with 3D printing?

Common cybersecurity threats associated with 3D printing include IP theft, data breaches, deliberate insertion of defects, and vulnerabilities to cyberattacks due to cloud-based operations.

How to Combat Cybersecurity Risks in 3D Printing?

Combatting cybersecurity risks in 3D printing involves implementing the finest cybersecurity standards, securing sensitive data, monitoring for potential threats, and staying updated on the latest security measures.

What are 5 facts about 3D printing?

3D printing is used in the film industry, it’s older than you think, it’s not just for prototyping, it’s called fashion, and it lets you print almost anything.

What is the main risk associated with 3D printing?

The main risks associated with 3D printing include environmental problems, gun and drug control issues, copyright infringement, and potential health hazards.

What are 5 facts about 3D printing?

3D printing is used in the film industry, it’s older than you think, it’s not just for prototyping, it’s called fashion, and it lets you print almost anything.

What is the main risk associated with 3D printing?

The main risks associated with 3D printing include environmental problems, gun and drug control issues, copyright infringement, and potential health hazards.

What are the common cybersecurity threats associated with 3D printing?

Common cybersecurity threats associated with 3D printing include IP theft, data breaches, deliberate insertion of defects, and vulnerabilities to cyberattacks due to cloud-based operations.